More Information

Submitted: September 28, 2023 | Approved: October 10, 2023 | Published: October 11, 2023

How to cite this article: Ashrapov U, Sadikov I, Bozorov E, Kamilov I, Kroshkin E, et al. Development of Gamma Flaw Detectors for Non-Destructive Testing. Int J Phys Res Appl. 2023; 6: 185-188.

DOI: 10.29328/journal.ijpra.1001070

Copyright License: © 2023 Ashrapov U, et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Gamma flow detector; Neutron irradiation; Ionization radiation source; Iridium-192

Development of Gamma Flaw Detectors for Non-Destructive Testing

Ulugbek Ashrapov1* , Erkin Bozorov1, Ismatilla Kamilov1, Evgeny Kroshkin2 and Valery Nesterov2

, Erkin Bozorov1, Ismatilla Kamilov1, Evgeny Kroshkin2 and Valery Nesterov2

1Institute of Nuclear Physics of Academy of Sciences (INPAS), Khurason Street 1, 100214, Tashkent, Uzbekistan

2Joint-Stock Company "Scientific Research Institute of Technical Physics and Automation" (JSC NIITFA), Varshavskoe highway 46, 115230, Moscow, Russia

*Address for Correspondence: Ulugbek Ashrapov, Institute of Nuclear Physics of Academy of Sciences (INPAS), Khurason Street 1, 100214, Tashkent, Uzbekistan, Email: ashrapov@inp.uz

The radiographic method of control is implemented by a set of control tools in the form of gamma flaw detectors, which are distinguished by: mobility, reliability, radiation safety, adaptability to a wide climatic range, ease of operation, and the ability to control products with small and large radiation thicknesses. The paper describes portable gamma flaw detectors manufactured by JSC NIITFA: Gammarid 2010R, UNIGAM R, Stapel-5 Se75 Ir192, Stapel-5 Se75W, gamma flaw detector γ-RID-75/80R and stationary gamma flaw detectors RID K-100 and RID K-400. Also paper describes a brief technology for the production of ionizing radiation sources Ir-192 with activity of 120 Curie, a technology for rolling the source holder with Ir-192 source and completing the Ir-192 source with a portable gamma flaw detector Gammarid-192/120M in the INP AS.

For the radiographic method of Non-Destructive Testing (NDT) quality control of welds and the degree of destruction of metal structures (process equipment, pipelines and various products), closed sources of ionizing radiation with radionuclides are used: Thulium-170 (Tm-170) for determining defects up to 10 mm; Selenium-75 (Se-75) for determining defects up to 40 mm, Iridium-192 (Ir-192) for determining defects up to 80 mm and Cobalt-60 (Co-60) for determining defects up to 200 mm are used. Radiographic control is designed to control the quality of welded joints of steel pipes and metal structures with a wall thickness of 5 mm to 200 mm, assemblies and parts of industrial products in the areas of thermal and nuclear energy, oil and gas complex, mechanical engineering, shipbuilding, and chemical production. The radiographic method of NDT provides: - reliability of information about the defect in the control object; - the possibility of monitoring the dynamics of the development of defects in the process of operation of the controlled object; - the possibility of archiving and documenting information about the controlled object. In the oil refining industries, numerous spectral methods of non-destructive testing are widely used: ultrasonic, radiographic, magnetic particle, acoustic emission, capillary, and all of them have their advantages and disadvantages. However, in the last resort, the radiographic method of control is used, because for all its shortcomings (high cost of equipment, the need to ensure the safety of personnel), only it allows you to determine with great accuracy the size of the defect and its location in the thickness of the metal of the pipe or weld. In addition, only the radiographic method of control allows monitoring the condition of pipelines without removing the insulation and preliminary surface preparation, which increases its economic viability, and the method can also be applied without stopping the operation of the pipeline [1-3]. Given the very diverse range of pipelines - from main pipes with a diameter of more than 1 meter with a wall thickness of up to 30 mm to pipes with a diameter of 10-14 mm with a wall thickness of 2 mm, radiographic control equipment should be universal, which is achieved by using a wide range of ionizing radiation sources as Tm-170 for short focal lengths, Se-75 for medium focal lengths, and Ir-192 and Co-60 for long focal lengths.

Joint-Stock Company "Scientific Research Institute of Technical Physics and Automation (JSC NIITFA) has many years of experience in the development and manufacture of gamma flaw detectors of various modifications: Gammarid 2010R (Gamma source Ir-192 2010 release), UNIGAM R (Universal gamma radiation), Stapel-5 Se75 Ir192 (Slipway-5 for Se-75 and Ir-192), Stapel-5 Se75W (Slipway-5 for Se-75 with tungsten protection), gamma flaw detector γ-RID-75/80R (Gamma source Se-75 with activity 80 Ci) and stationary gamma flaw detectors RID K-100 (Gamma source Co-60 with activity 100 Ci) and RID K-400 (Gamma source Co-60 with activity 400 Ci). One of the areas of development of JSC NIITFA is portable and stationary gamma flaw detectors and radioactive closed ionization radiation sources (Se-75, Tm-170, Ir-192, Co-60) for them.

Gamma flaw detectors of Gammarid-192/120M (gamma flaw detector with source Ir-192 with maximal activity 120 Ci modernized) based on Ir-192 ionization radiation sources with an activity of 4440 GBq (gigabecquerel) or 120 Ci are widely used in the Republic of Uzbekistan for quality control of products in industrial enterprises. However, the import of Ir-192 sources to Uzbekistan is associated with certain difficulties associated with meeting the requirements for the movement and customs clearance of radioactive sources. Therefore, the manufacture of Ir-192 sources of domestic production and their completion with gamma flaw detectors Gammarid-192/120M, which are the property of the Institute of Nuclear Physics of the Academy of Sciences (INP AS) of Republic Uzbekistan was an urgent task. The goal of the project was to develop a technology for the production of highly active Iridium-192 sources and their equipment with gamma flaw detectors Gammarid-192/120M based on the WWR-SM reactor and the Republican Central Isotope Laboratory (RCIL). INP AS has developed a unique technology for producing the 192Ir radionuclide by irradiating natural iridium disks with reactor neutrons in the vertical channels of the WWR-SM reactor (water–water reactor serial modernization) based on the 191Ir(n, γ)192Ir nuclear reaction and manufacturing sealed sources of Ir-192 with activity of 120 Ci, developed technology of rolling the source holder and loading the source holder into the radiation head of the Gammarid-192/120M gamma flaw detector and also technology for recycling spent Iridium-192 sources.

Gamma flaw detectors manufactured by JSC NIITFA

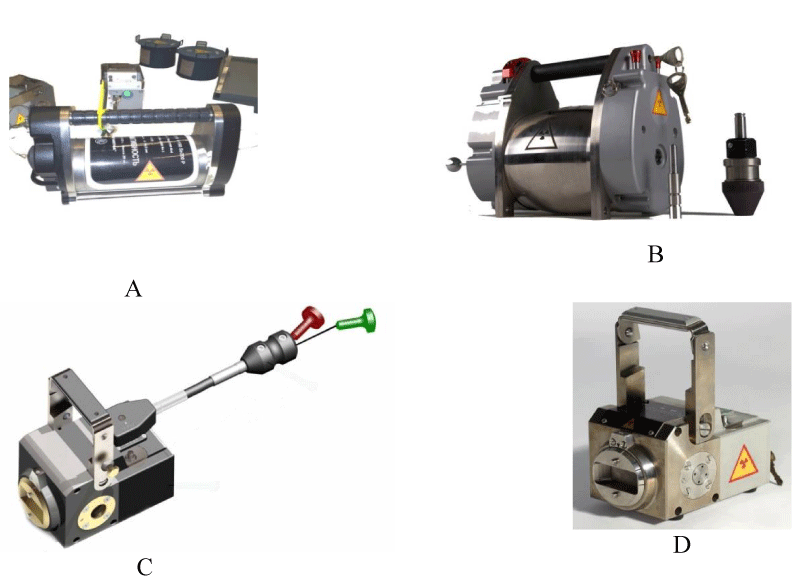

It is preferable to use gate-type gamma flaw detectors that create a collimated radiation beam, which can be perceived by the detection system with an online image on a computer monitor while the radiation source is constantly moving along the pipeline. The high degree of reliability and proposed design of the movement of the gamma flaw detector, rigidly connected to the radiation detector, will make it possible to determine not only the exact location of the weld and the degree of its wear but also defects in the base metal of pipes, such as thinning of the walls as a result of corrosion, violation of geometry as a result of unforeseen static loads, cracks and accumulations of microcracks, as well as other deviations that are not allowed in accordance with the regulations for the operation of pipeline valves. Figure 1 shows portable gamma flaw detectors manufactured by JSC NIITFA.

Figure 1: Portable gamma flaw detectors manufactured by JSC NIITFA: A - Gamma flaw detector "Gammarid 2010R" universal - hose type with a universal collimator; B - Portable gamma flaw detector "UNIGAM R" with an axial gate channel; C and D- Gamma flaw detector "Stapel-5 Se75 Ir192" shutter type.

We also see the technical characteristics of portable gamma flaw detectors GAMMARID 2010 R and Stapel-5 Se75 Ir192, Stapel-5 Se75W, γ-RID-75/80R manufactured by JSC NIITFA in Tables 1 and 2, respectively [4].

| Таble 1: Technical characteristics of the radiation heads of the gamma flaw detector GAMMARID 2010 R [4]. | ||

| Parameter | Ir-192 source with activity 150 Ci | Ir-192 source with activity 300 Ci |

| Weight of the radiation head, kg | 20.0 | 19.7 |

| Dimensions (H x B x L) radiation head, mm | 197 х 120 х 352 | 227 х 168 х 310 |

| Radiation source: Type; ratings Exposure Dose Rate, A/kg; Activity, Becquerel - Bq (Ci) | Ir-192 type GIID-192М34.6; Ir-192 type GIID-192М34.7; 5.1 х 10-6 ; 5.6 х 1012(150) |

Ir-192 GIID-11а-4; 6.8 х 10-6; 11.1 х 1012(300) |

| Bio-protection material | depleted uranium | depleted uranium and metal tungsten |

| Таble 2: Technical characteristics of portable gamma flaw detectors Stapel-5 Se75 Ir192, Stapel-5 Se75 W and γ-RID-75/80R. | |||

| Name | Stapel-5 Se75 Ir192 |

Stapel-5 Se75W |

γ-RID-75/80R |

| Weight of the protective radiation head, kg | 10 | 10 | 6 |

| Closed Ionizing radiation source | Ir-192; Se-75 | Se-75 | Se-75 |

| Effective energy of gamma radiation, MeV | Ir-192 – 0,40 Se-75 – 0,215 |

Se-75 – 0,215 | Se-75 – 0,215 |

| Optimum controlled thickness (steel), mm | Ir-192 – 10-80 Se-75 – 5-40 |

5 - 40 | 5-35 |

| Half-life of a radionuclide, T1/2 | Ir-192 – 74 days Se-75 – 120 days |

Se-75 – 120 days | Se-75 – 120 days |

| Source activity, Ci, up to | Se-75 – 80; Ir-192 - 70 | Se-75 - 80 | Se-75 - 80 |

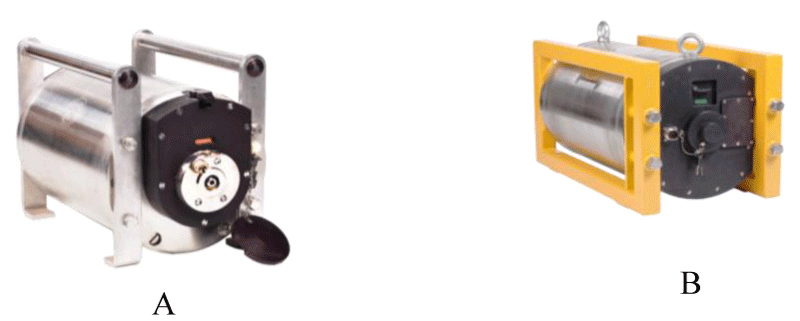

JSC NIITFA has developed and manufactured stationary gamma flaw detectors using a source based on radionuclide 60Co for NDT of welded joints with a transmission depth of up to 200 mm in steel, or for detecting discontinuities and heterogeneous inclusions in critical products from other materials. Ionization radiation source Co-60 in these devices moves along the ampoule line using an electromechanical drive when transmitting commands from the control panel with movement both horizontally and vertically. Figure 2 shows stationary gamma flaw detectors manufactured by JSC NIITFA. The technical characteristics of stationary gamma flaw detectors RID K-100 and RID K-400 are presented in Table 3.

Figure 2: Stationary gamma flaw detectors manufactured by JSC NIITFA: A – stationary gamma flaw detector RID K-100; B- stationary gamma flaw detector RID K-400.

Table 3: Technical characteristics of stationary gamma flaw detectors RID K-100 and RID K-400. |

||

| Parameter | Description | |

| RID К-100 | RID К-400 | |

| Co-60 ionization radiation source activity, Ci | 100 | 400 |

Half-life of radionuclide Co-60, year |

5,27 | 5,27 |

| Effective energy of gamma radiation, MeV | 1,25 | 1,25 |

| Controlled thickness range (steel), mm | 30… 200 | 30…200 |

| Weight of the radiation head, kg | 152 | 293 |

Dimensions (H x B x L) radiation head, mm |

450 х 270 х 320 | 50 х 270 х 320 |

| Bio-protection material | depleted uranium | depleted uranium |

Gamma flaw detector manufactured by INP AS

In the INP AS a unique technology for the production of a sealed ionization radiation source of Iridium-192 with an activity of 120 Ci was developed, a technology for rolling the source holder with an Ir-192 source and technology of completing the Ir-192 source with a portable gamma flaw detector Gammarid-192/120M [5].

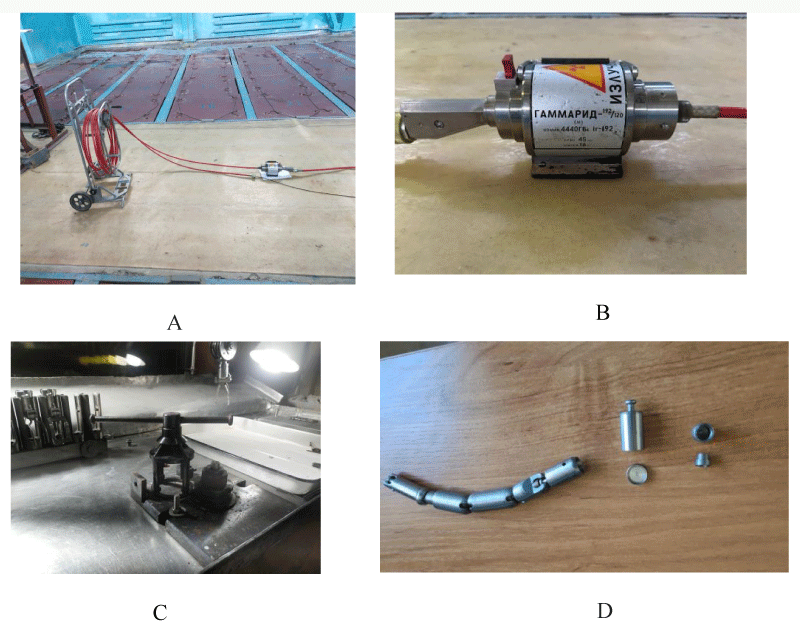

Briefly about the manufacturing technology of the Ir-192 source and its complication with Gammarid-192/120M: Metal disks of natural iridium (diameter, ∅ = 2.7 mm; thickness, h = 0.2 mm; weight, m = 31.7 mg) in quantity 20 - 30 pieces packed in aluminum foil, which were irradiated in the vertical channel of the reactor in the block container EK-20 (experimental channel with a diameter of 20 mm) [6] at a nuclear WWR-SM reactor with power of 10 MW, thermal neutrons flux density is 0.9⋅1014 neutron/cm2sec and irradiation time - from 600 to 1680 hours. In the reactor “hot chambers” packages with irradiated iridium disks are placed on a special device for radiochemical processing, where radioactive iridium disks are released from the packaging, treated with an alkali solution, water, and dried. On the special device neutron-irradiated iridium disks were placed in a magnetic stainless steel capsule, the capsule was closed with a lid and welded by spot argon-arc welding the tightness of the Ir-192 source was checked by the immersion method [7]. In a protective chamber with manipulators on a special installation, the Ir-192 source was placed into the source holder capsule, which was provided with a lid, and the holder was rolled, then the holder to a flexible shaft was connected. The holder with the Ir-192 source to the flexible shaft of the ampoule wire was connected and the recharge container was charged by remote method. Table 4 shows the main technical characteristics of the Ir-192 source manufactured by INP AS [8]. The main technical characteristics of the gamma flaw detector Gammarid-192/120M are shown in Table 5. Also, Figure 3 presents the gamma flaw detector Gammarid-192/120М of the INP AS.

Figure 3: Gamma flaw detector Gammarid-192/120М: A - Trolley, ampoule line 17 m long and radiation head; B- Radiation head of the gamma flaw detector; C - Photo of a device for remote rolling the Ir-192 source holder inside a protective box of RCIL; D - Flexible shaft ampulla wire, holder for Ir-192 source with lid, source simulator with cover.

| Table 4: Main technical characteristics of the source Ir-192 [8]. | |

| Name, characteristic, and unit of measure | Data |

|

bottom |

| The value of the Exposure Dose Rate (EDR) of gamma radiation measured by direct measurements by using a dosimeter of the IdentiFinder Target type (No. 910385 - 495) at a distance of 1.0 m from the surface of the radiation head of the Gammarid 192/120M gamma flaw detector (No. 706 – 1990) of source Ir-192 A/kg (R/h), mR/h | 3,87 × 10-6 ; (54); 1.0 |

| Confidence limits of the total error of the results measurements of the exposure dose rate of a source at a probability of 0.95, in % | ± 20 |

|

18.07.2023 |

|

4.44×1012 (120) |

|

Æ– 4,5; h– 8,0 |

| Dimensions of the active part of the source, mm | Æ– 3,0; h– 4,5 |

| Capsule material | Stainless steel 12X18H10T |

| Source tightness | sealed capsule |

| The level of radioactive contamination of the source with radioactive substances when determined by the method- smear removal, Bq, no more | 185 |

| Table 5: Technical characteristics of gamma flaw detector Gammarid-192/120M. | |

| Parameters | Description |

| Weight of the radiation head, kg | 16 |

| Radiation source: Type, ratings EDR, A/kg; Activity, Bq (Ci) | Ir-192; 3.58×10-9 ; 4.44×1013 (120) |

| Bio-protection material | depleted uranium |

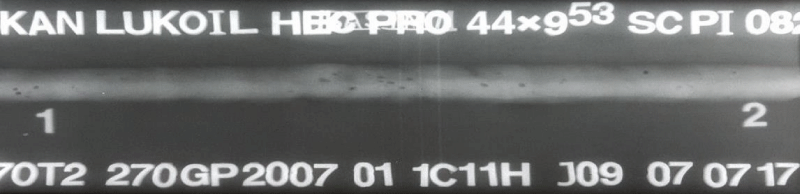

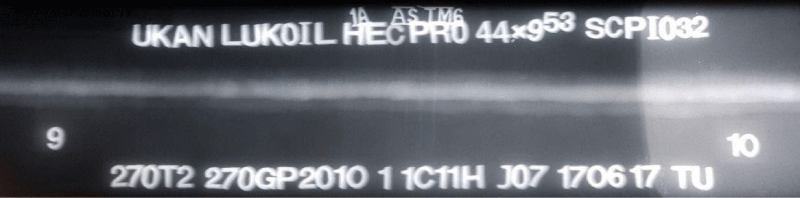

The gamma graphic method was carried out at the Kandym gas processing plant, Figures 4 and 5 show X-ray images of samples of welded joints of pipelines obtained by the Gammarid-192/120M with an Ir-192 source manufactured by the INP AS.

Samples of the X-ray images of NDT obtained by Ir-192 source manufactured in INP AS (Figures 4 and 5), in terms of sensitivity and quality, meet the requirements of the international standards for non-destructive testing [9]. Gamma graphic NDT images obtained by specialists of the Limited Liability Company "VBM-Engineering" and foreign partners working at these production facilities, as a third-party inspection, were assessed as fully meeting the requirements of the international darts standards [10,11], valid on the territory of the Republic of Uzbekistan.

Figure 4: X-ray image of a weld sample with a diameter of 1020.0 mm, obtained using the method of gamma radiography with an Ir-192 source, where accumulations of gas pores and slag inclusions are clearly visible in the weld sample.

Figure 5: X-ray image of a weld sample with a diameter of 1020.0 mm, obtained after eliminating defects in the weld (Figure 4), repeated using the gamma radiography method with an Ir-192 source, where the image shows that there are no defects in the weld.

The high technological level and competitiveness of high-tech products of JSC NIITFA are confirmed by the fact that gamma flaw detectors and radioactive sources produced were supplied to the CIS countries and more than twenty other countries of the world, including the USA, England, Germany, Belgium, Finland, China, Vietnam, India, Bangladesh, Portugal, Peru, Cuba, Bulgaria, Czech Republic, Slovakia, Poland.

The Iridium-192 sources produced by the INP AS together with gamma flaw detectors Gammarid-192/120M were successfully used in Talimarjan TPP (Kashkadarya region), Takhiatash TPP (Karakalpakstan), Syrdarya TPP (Syrdarya region), Kandym gas processing plant (Bukhara region). Gamma graphic NDT images obtained by specialists of the Limited Liability Company "VBM-Engineering" and foreign partners working at these production facilities, as a third-party inspection, were assessed as fully meeting the requirements of the international darts standards valid on the territory of the Republic of Uzbekistan.

- Oliveira DF, Soares SD, Lopes RT. Inspection of Composite Pipelines using Computed Radiography. 5th Pan American Conference for NDT. Cancun, Mexico. 2011;16:(12);9. https://www.ndt.net/search/docs.php3?id=11257.

- Hayward P, Zeak H, Currie D. Radiography of weld using selenium75, Ir 192, and X-rays. 12th A-PCNDT 2006 – Asia-Pacific Conference on NDT. Auckland, New Zealand. 2006; 5. https://www.ndt.net/?id=4206

- Mintern RA. Gamma Radiography with Iridium192. Advantages In The Non-Destructive Testing Of Castings And Welded Structures. Journal Archive Platinum Metals Rev. 1959; 3:(1); 12. https://technology.matthey.com/article/3/1/12-16/

- Lobzhanidze TK, Dekopov AS, Mikhailov SV. Hose gamma flaw detector. Patent of the Russian Federation No. 2473073, 2000.

- Ashrapov UT, Khujaev SS, Sadikov II, Tashmetov MY, Isaev YA. Manufacturing of an Iridium-192 Ionizing Radiation Source for Nondestructive Testing. Journal of Physics of Atomic Nuclei. 2021; 84:9; 1540–1549. https://trebuchet.public.springernature.app/get_content/66e2abef-fb16-4305-91e0-3bf86217a112

- Yuldashev BS, Ashrapov TB, Mirzaev NM, Ashrapov UT. Container for irradiating samples in the reactor. Provisional patent of the Republic of Uzbekistan No. IDP04633 (2000).

- Ergashev KhA, Makhkamov ShM, Ashrapov UT. Method for checking the tightness of the ionizing radiation source. Provisional patent of the Republic of Uzbekistan No. 4943, 1997.

- Passport No. 02/23 for a gamma radiation source closed with the radionuclide Iridium-192. Tashkent, INP AN RUz. 2023; 4.

- Ashrapov UT, Khyjaev SS, Isaev YA. Manufacturing of ionizing radiation source of iridium-192 for gamma-defectoscopes Gammarid-192/120М. Joint Stock Company «National technical physics and automation research institute» (JSC «NIITFA»), Moscow, Russia. 2017; 77:55-69. http://www.niitfa.ru/upload/docs/vant/vant_tfa-77.pdf;

- ASME Nondestructive Examination and Quality Control Central Qualification and Certification Program, ANDE-1, USA. 2020; 33.

- GOST-7512-82. Non-destructive testing. Connections are welded radiographic method. Moscow: Standartinform. 2008; 19.